Foresight’s Li-ion Battery Manufacturing Machines are advanced intelligent systems designed to enhance precision, quality, and efficiency across lithium-ion battery production. Featuring proprietary Spot-Coating Technology, the equipment enables patterned coating on electrodes and separators with superior uniformity and energy efficiency. Covering key stages such as coating, drying, and precision slitting of separators, copper, and aluminum foils, the systems integrate real-time monitoring and intelligent control algorithms to ensure high-speed, stable, and consistent performance for next-generation lithium-ion battery manufacturing.

Foresight’s proprietary Spot-Coating Technology replaces traditional spray coating with controlled, patterned application. Each droplet is deposited with micron-level precision, reducing edge overflow, splashing, and overspray while ensuring uniform coating thickness.

Compared with spray coating, spot-coating significantly lowers solvent consumption and drying energy. The precise coating pattern minimizes material waste and enables stable, high-speed production with cleaner, more efficient drying performance.

The system integrates AI-based motion control, tension feedback, and real-time monitoring to maintain coating accuracy under variable conditions—ensuring consistent quality and long-term process stability.

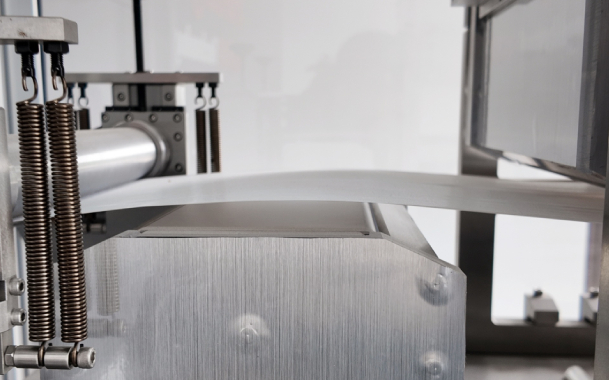

Air-Floatation Drying for Contact-Free Precision

Foresight’s Air-Floatation Oven System uses balanced airflow to support materials without mechanical contact, achieving uniform two-side drying, improved surface quality, and superior temperature control at high speeds.

AI-Enhanced Process Optimization

By combining data-driven modeling, predictive algorithms, and intelligent feedback loops, the system continuously optimizes coating uniformity, tension stability, and drying efficiency—delivering adaptive control for every production scenario.

Advanced Research and Engineering Integration

Backed by continuous R&D in fluid dynamics, precision motion, and automation engineering, Foresight’s solutions represent the forefront of next-generation battery coating and manufacturing technology, ensuring lasting innovation and performance leadership.